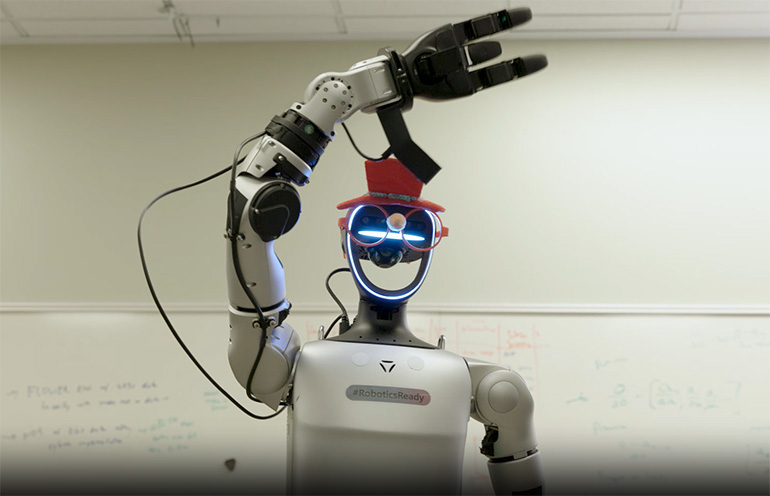

The AX Motion Insights platform integrates AI with maintenance workflows, enabling distribution and fulfillment operations to predict points of failure, plan interventions, and reduce unplanned downtime. | Source: Festo

While automation promises a future where robots can do work around the clock, seven days a week, without tiring, downtime caused by unexpected issues still holds us back from that future. Festo this week introduced its new Festo AX Motion Insights platform, which it said can reduce unplanned downtime in robotics.

The platform combines AI-based predictive analytics with maintenance workflows, which Festo said can reduce unplanned downtime across conveyors, sortation systems, palletizers, gantries, and material-handling equipment.

This latest platform works with Festo’s existing software lineup. Festo AX Motion Insights Electric software monitors servo drives and electric axes. AX Motion Insights Pneumatic software provides condition monitoring for pneumatic cylinders.

AX Data Access serves as the data layer that makes operational technology (OT) data available for information technology (IT) analysis and integration. Together, Festo said the platforms enable fulfillment centers to scale predictive maintenance capabilities as needs develop rather than committing to a single, monolithic software rollout.

Festo said the platform provides flexible deployment options that support on-premises and cloud-based environments. This allows fulfillment and distribution centers to align predictive maintenance with existing IT and operational requirements while maintaining control over how and where data is collected and used.

Festo is a global manufacturer of pneumatic and electromechanical systems, components, and controls for process and industrial automation. The company has subsidiaries in more than 60 countries, and a wide-ranging 36,000-product catalog.

Motion Insights looks for problems, then takes action to prevent them

Motion Insights identifies where problems are likely to occur. Smartenance AX, Festo’s maintenance management software, is the link to action. Smartenance AX turns predictive insight into planned maintenance by directing crews to the most likely point of failure instead of reacting after a machine stops.

It combines asset tracking, maintenance planning, and a digital machine logbook, allowing condition data from Motion Insights to trigger targeted maintenance tasks. In addition to Smartenance AX, Motion Insights can also be integrated with other maintenance management systems, allowing condition data to inform existing workflows where customers prefer to keep their current platforms.

AX Motion Insights Pneumatic provides universal condition monitoring for pneumatic cylinders from all manufacturers without requiring additional sensors, hardware changes, or mechanical modifications. The software detects anomalies and performance drift in pneumatic motion, identifying not only impending failures, but also underperformance that can lead to inconsistent handling, increased air consumption, and throughput loss.

AX Data Access connects automation systems to enterprise IT environments by making operational data available for analysis beyond the control layer. By bridging OT and IT, AX Data enables fulfillment centers to correlate motion performance, maintenance activity, and energy use with broader operational metrics.

Festo plans for scale and easy deployment

AX Motion Insights software is scalable by design. Machine builders and system integrators purchase licenses only for the functions and assets they need, with the ability to expand coverage over time as automation requirements evolve.

Machine builders and system integrators can incorporate AX motion insights software into their after-sales support contracts as a value-added service for their customers.

AX Motion Insights Electric integrates directly with Festo CMMT multiprotocol servo drives and electric axes used throughout fulfillment center automation systems. Festo multiprotocol servo drives are compatible with the leading industrial communication protocols, allowing a single drive platform to operate across mixed PLC and network environments.

This simplifies standardization, reduces hardware variation in inventory, and helps system integrators commission and support automation systems more efficiently, Festo claimed. The company plans to include support for additional brands of servo drives and axes.

The post Festo introduces AI-based predictive maintenance platform to improve automation uptime appeared first on The Robot Report.