Aerospace manufacturing could lead the way to integrating automation and AI, says Flexxbotics. Source: Flexxbotics

The news that SpaceX is bringing xAI into its core operations isn’t just another big tech acquisition. In his announcement, Elon Musk made the near-term implications surprisingly concrete for anyone working in automation and robotics.

It described the massive scale of rocket and satellite production as a “forcing function” similar to how SpaceX’s launch demands have driven rapid improvements in engineering and flight operations. In practical terms, that means AI isn’t being adopted as an experiment or side project. It’s being pulled directly into the heart of the company‘s automated production because the volume, speed, and complexity of manufacturing now require it.

When output must scale by orders of magnitude, manual optimization, disconnected data systems, and slow process learning simply can’t keep up. AI becomes necessary to:

- Understand complex production behavior in real time

- Detect issues before they cascade into failures

- Continuously improve processes instead of periodically re-engineering them

This is the real signal for factory automation: AI is shifting from isolated pilot projects and analytics tools into automated production infrastructure.

In other words, AI isn’t being added to automated manufacturing. Automated manufacturing is being rebuilt around AI-driven learning and control.

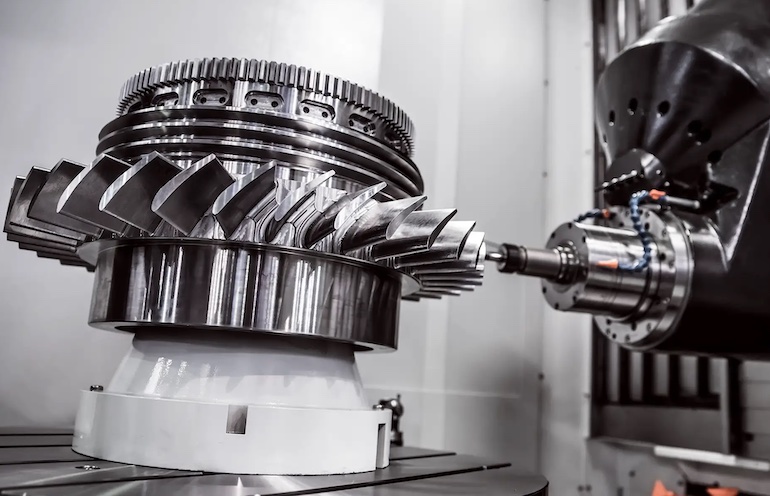

Manufacturing for space is already one of the most demanding production environments on Earth, with extreme tolerances, complex assemblies, massive volumes of data, and zero margin for error. When you combine this kind of operation with serious AI capabilities, you get a preview of where industrial automation is heading more broadly.

From my perspective, this deal accelerates several trends we’re already seeing across leading manufacturers and will push them forward faster.

Precision manufacturing is about to become far more adaptive

Most high-precision factories today still rely on manually engineered static recipes:

- Set parameters.

- Control variation.

- Inspect at the end.

That approach works when conditions are consistent for long periods. However, it’s slow to adapt, vulnerable to drift, and expensive to validate, especially when production requirements introduce changes at a rapid pace.

With advanced AI directly embedded into automated production systems, precision manufacturing will start behaving more like a continuously learning process:

- Robotic applications will adapt processing based on real-time feedback.

- Workflows can adjust to material and environmental variation instead of rejecting parts.

- Quality can be predicted during production instead of discovered after the fact.

- Process windows are optimized dynamically instead of locked down.

This isn’t about replacing deterministic control. From my perspective, it’s about layering intelligence on top of it so software-defined automation can respond to reality instead of hard-coded assumptions of perfection.

In aerospace factories — where tolerances are extreme and production changes frequently — that adaptability is a huge advantage and a necessity for what Musk is outlining. And once proven in such stringent conditions will be adapted for additionally demanding industries including semiconductors, pharmaceuticals, automotive, and others.

SpaceX could be a pioneer, not just in spaceflight, but for other industries, says Flexxbotics’ CEO. Source: SpaceX

The real SpaceX advantage is the data, not just the models

What makes this combination so powerful isn’t just better AI in factory automation. It’s the scale and richness of SpaceX’s existing production data that will feed it.

The company already generates exhaustive industrial data sets:

- High-frequency machine telemetry

- Vision and imaging across inspection and assembly

- Process parameters from every step

- Environmental conditions

- Quality results and rework records

- Test and validation data

- Performance data from systems in operation

When all this data is available, connected, and contextualized, AI can learn how production decisions affect real outcomes on an ongoing basis, including reliability, performance, failures, production, lifecycle behavior.

That’s something most factories struggle to do today because data are siloed, inaccessible, and incompatible:

- The robot has its logs.

- The PLC has its tags.

- The quality system has its reports.

- The historian has its time series sets.

- The MES (manufacturing execution system) has its genealogy.

Rarely does it all come together in a contextualized way that industrial AI can use effectively.

This kind of vertically integrated production environment creates AI training data that’s meaningful in addition to being large. And meaningful multi-source data is what fuels AI from a reporting tool into a control and optimization engine.

Flexxbotics last week updated a FANUC industrial robot driver for machine interfacing in an open-source project. Source: Flexxbotics

Anomaly detection moves from alerts to real diagnostics

One of the most practical near-term impacts of the SpaceX consolidation with xAI will be in how SpaceX factories detect and respond to process issues.

Today, anomaly detection often looks like: “Something drifted. Here’s an alert.” Then engineers spend days or weeks digging through logs, charts, and spreadsheets to figure out what actually happened.

With AI trained across multimodal production data:

- Subtle process drift gets caught early

- Patterns across machines and operations get correlated automatically

- Likely root causes can be surfaced in minutes, not weeks

- Corrective actions can be tested digitally before changing the line

- Automated manufacturing compliance can be introduced incrementally

This has big implications for:

- Faster validation of new robotic factory processes

- Shorter qualification cycles

- Reduced scrap and rework

- Quicker ramp to volume

Over time, it also becomes predictive and prescriptive. In addition to telling you what is out of spec, the system can alert you to what’s about to go out of tolerance, why, and what to do to make corrections.

Instead of reacting to failures, factories can manage automated process health continuously.

The SpaceX and xAI combination could advance software-defined manufacturing. Source: Flexxbotics

SpaceX manufacturing drives compliance in AI automated processes

AI’s expansion across robotic application use cases in aerospace manufacturing will force production-grade compliance and governance.

Rocket manufacturing doesn’t allow “black box” systems making uncontrolled alterations. Everything requires traceability, documentation, and controlled change subject to AS9100 and AS9100D. That means as SpaceX further integrates AI into automated space production, it will have to support:

- Full data lineage

- Model versioning and approval workflows

- Explainable decisions and outputs

- Human sign-offs where risk is high

- Clear audit trails

This is actually great news for the broader manufacturing world. Some of the reasons why industrial AI and agentic adoption have been slower than in other industries are trust, traceability, and compliance. Manufacturing teams cannot allow systems to operate in mission-critical production that are not understood, validated, and explicitly controlled.

Building AI inside some of the most regulated manufacturing environments in the world will drive better compliance, governance, transparency, and safety frameworks into software-defined automation. Robotic applications can then be applied across other regulated industries.

In short, AI governance in industrial robotics and automation could mature much more rapidly than otherwise possible.

Aerospace manufacturing requires fine tolerances and flexibility. Source: SpaceX

AI shifts from ‘analytics layer’ to automation control logic

Most factories today treat AI like a proof-of-concept add-on, with standalone robot motion tools, isolated vision systems, dashboards and reports. This approach is incredibly limited.

What we can expect from SpaceX + xAI — and what this kind of vertically integrated, end-to-end approach enables — is AI moving directly into the automation application layer:

- Managing workflows across machines

- Coordinating factory-wide robotic cells

- Providing closed-loop control

- Triggering quality interventions

- Adjusting processing variables

- Orchestrating robotic production in real time

Instead of just telling people what happened, AI becomes part of how the automated factory runs. This is when autonomy really starts to scale out.

Physical AI, edge AI, and industrial AI finally connect

True autonomous manufacturing isn’t one type of AI. It’s coordination across multiple layers:

- Physical AI: Embodiment in robots, machines, and individual pieces of equipment doing the work

- Edge AI: Real-time inference for cell applications and process-level operational coordination, anomaly detection, safety-critical decisions

- Industrial AI: Plant-level orchestration, prescriptive optimization, self-learning across fleets, predictive agentic models

Today, these layers are disconnected and operate independently for the most part.

AI ecosystem integration enables continuous feedback between all three, where learning at the factory level improves control at the machine level and real-world performance continuously retrains higher-level models. That loop is what turns automation into autonomy.

What this means for the future of industrial robotics

The biggest takeaway isn’t that one company will build smarter factories. It’s that the timeline for autonomous manufacturing just got shorter. We’re likely to see:

- Standardized interoperability for real-time data architectures becomes the norm

- AI embedded directly into production processes at the robotic application level

- Software-defined automation layers with AI orchestrating diverse equipment workflows

- Closed-loop, real-time feedback replacing static recipes and fixed robot programs

- Digital thread regulatory compliance to feed continuous learning systems

This is where intelligence, interoperability, and control are driven by standard AI-enabled software instead of hardware-locked systems and custom integrations.

SpaceX manufacturing facilities will simply be the first large-scale proving grounds.

SpaceX and xAI combo will have a practical impact

While the SpaceX and xAI combination may generate futuristic headlines, the near-term outcome will be a step function toward practical autonomy in our industrial robot reality.

The immediate result will be the rapid insertion of advanced AI inside some of the most demanding factory environments in the world where precision, reliability, safety, and scale all matter at once.

This forcing function, as the xAI announcement referred to it, will produce better AI architectures for industrial robotics and factory automation, including:

- Stronger data contextualization foundations

- Real governance and compliance frameworks

- Practical closed-loop manufacturing autonomy

For those of us building and deploying autonomous manufacturing platforms today, this isn’t a distant future vision. It’s confirmation of the direction our industry is already heading.

The factories of the future won’t just be automated. They’ll be autonomous.

Intelligent systems continuously learning, self-optimizing, and orchestrating production through AI-enabled software-defined automation. And this acquisition may be one of the seminal moments that accelerates our journey into that future.

About the author

About the author

Tyler Bouchard is co-founder and CEO of Flexxbotics, a provider of digitalization solutions for robot-driven manufacturing. Prior to starting Flexxbotics, he held senior commercial positions in industrial automation and robotics at Fortune 500 organizations including Cognex, Mitsubishi Electric, and Novanta.

Bouchard holds a bachelor’s degree in mechanical engineering from Worcester Polytechnic Institute and attended the D’Amore-McKim School of Business at Northeastern University.

The post What the SpaceX acquisition of xAI means for industrial robotics appeared first on The Robot Report.