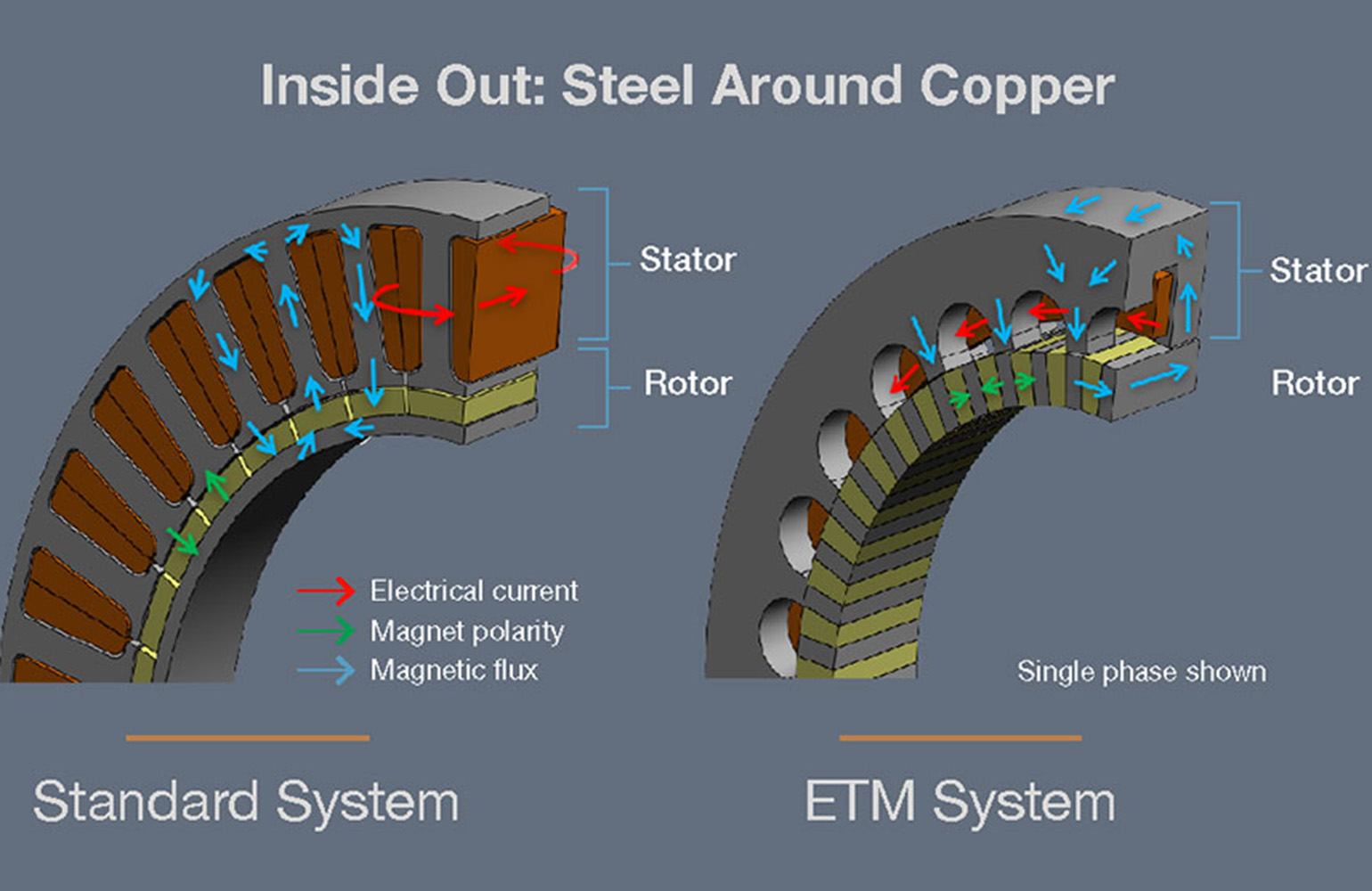

Conventional motors feature copper wrapped around steel, but ETM’s steel stator is wrapped around the outside of the low-resistance copper coil. | Source: ETM

Electric Torque Machines, or ETM, last week entered the robotics and advanced actuator market with its transverse flux motor technology. The company said it is offering its TFM technology through a flexible partnership model that allows OEMs to retain manufacturing control, protect margins, and accelerate development timelines.

The robotics industry faces converging pressures: aggressive performance targets, thermal management constraints, supply chain volatility, and the need for product differentiation, according to ETM. It said its TFM technology addresses these challenges at the system level, enabling manufacturers to simplify mechanical designs, reduce costs, and achieve performance benchmarks previously requiring significant tradeoffs.

“The era of sacrificing thermal performance for torque density is over,” stated Chuck Ensign, ETM president. “ETM provides robotics companies next-level actuation capability while maintaining control of their product roadmap and manufacturing destiny.”

Founded in 2007, ETM was acquired by Graco in 2020. The Flagstaff, Ariz.-based company’s TFM technology was initially used in high-volume, low-speed (HVLS) industrial fans. It now serves markets including marine propulsion, material handling, and pumps and sprayers, with new applications continuously under development and launch.

TFM promises to cut motor size and manufacturing cost

While high-ratio actuators maximize torque-to-weight ratios, their inherent inefficiency creates significant thermal bottlenecks and reduces battery autonomy, asserted ETM. Alternative direct-drive architectures attempt to improve efficiency but ultimately fail to meet SWaP-C2 (size, weight, power, cost, and cooling) targets due to excessive motor sizing and manufacturing costs, it said.

ETM said TFM eliminates this trade-off by decoupling magnetic flux from electrical windings, enabling the torque density of high-ratio systems with the efficiency and thermal reliability of low-ratio drives. The company claimed that its patented architecture provides up to 10x greater torque density than conventional motors.

In addition, ETM said its TFM technology has already been proven in demanding, high-volume industrial applications.

ETM has replaced the “rat’s nest” of copper wiring on a conventional motor with a simple, low-resistance circular coil. | Source: ETM

ETM licensing lets OEMs include motors in their own platforms

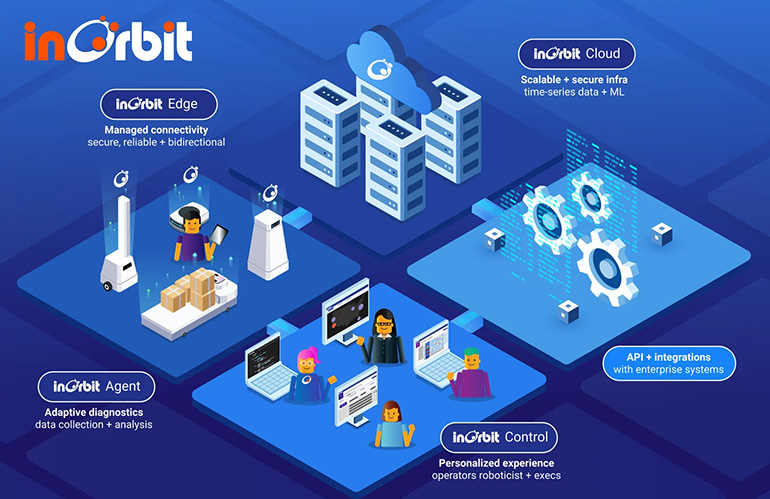

TFM provides robotics OEMs with an alternative path to relying on external component suppliers, said ETM. They can license its proven motor technology and manufacture it within their own platforms rather than relying on external component suppliers.

Unlike typical supplier relationships, ETM said its licensing model allows partners to retain full manufacturing control and margin while leveraging validated architecture—accelerating time-to-market and reducing technical risk. This enables OEMs to integrate TFM technology within their own designs, use existing manufacturing infrastructure, and maintain complete control over proprietary platforms.

ETM said its licensing model “turns the long-elusive TFM technology into a competitive advantage partners own, not a commodity they buy.”

The post ETM brings its transverse flux motor technology to robotics appeared first on The Robot Report.