New standards for force- and power-limited robots are intended to improve safety. Source: IDEC

Industrial automation continues as a fast-growing market, with manufacturers and end users of all types eager to reap the benefits of reliable and rapid execution for many types of tasks. Some people think of autonomous vehicles, remote-controlled drones, and software “bots” as robots, but industrial robots and cobots are characterized as programmable manipulators of three or more axes.

Many industries use traditional robots, which have experienced a 7% compound annual growth rate (CAGR) over the past five years, according to the International Federation of Robotics (IFR). However, the market for force- and power-limited robots — commonly referred to as collaborative robots or cobots — in its infancy, and the IFR predicted that its growth rate could be much stronger.

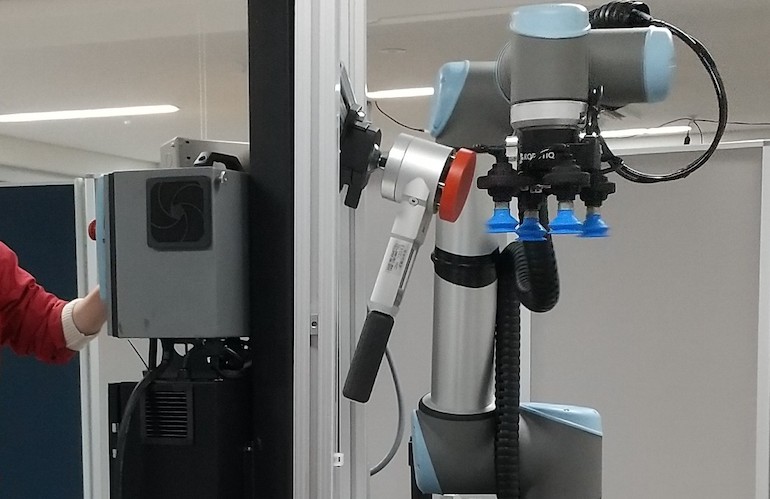

While both robots and cobot arms include provisions to protect workers, cobots are designed to work side-by-side with plant personnel. Various safety standards have been established for both types of systems, and each category has been independently recognized (Figure 1).

Figure 1: Robots and cobot standards are evolving, and this will affect how designers and original equipment manufacturers comply with safety requirements. Source: IDEC

The safety requirements for all types of robots are evolving. Designers, original equipment manufacturers (OEMs), and end users need to know what the new standards mean for their implementations, as explained below.

Standards differentiate for industrial robots and cobots

The classic industrial robot most people think of is large, powerful, and fast. It is ideal for applications that are difficult or dangerous for people, such as manipulating large payloads, repetitively performing accurate tasks, and/or operating in challenging environments.

There are many variations of these robots and the tools/grippers they use, but common examples of the tasks they perform are welding, painting, assembly, and material handling. These robots are typically located within safety-fenced work cells to keep plant personnel away from them when in operation.

Cobots are a subcategory of robots that are relatively lightweight and designed to collaborate with humans. Because speed and force are limited, such systems can operate in shared workspaces to safely to assist with, or completely perform, many tasks.

In addition, cobots are designed to be easily configured or programmed so they can be frequently re-deployed for multiple applications. Cobot makers say this feature democratizes the implementation of these systems.

Users often configure these robots by manually directing the manipulator arm through the desired operation. These characteristics enable cobots to be introduced into manual work environments where no such automation previously existed.

Previously, the ISO 10218 series standard applied to industrial robots and robot systems, while the ISO/TS 15066 standard addressed collaborative systems. A revised ISO 10218 series was published in 2025, with ISO 10218-1 addressing industrial robots, and ISO 10218-2 covering industrial robot systems, robot applications, and robot cells.

Effectively, all robot types are integrated into one standard series, without the previous robot/cobot distinction and differentiation. The same rules apply to all industrial robots, and the term “collaborative robot” is eliminated. Instead, the new ISO 10218 standards now emphasize that when an operator and a robot coexist or collaborate in the same space, then the entire system must be treated as a collaborative application.

Note that the industrial robot category includes the manipulator—consisting of one or more arms—and the associated controller and teach pendant. An industrial robot system includes the robot end effector or tool, work products, associated machinery, safeguards and sensing devices, and guard hardware.

A new class of robot is defined

With the new standard, two classes of robots are defined:

- Robot Class I: Defined as robots designed for a total manipulator mass of 10 kg (22 lb.) and under, with a maximum force of 50N and less, and a maximum speed of 250mm/s (0.5 mph) and under.

- Robot Class II: Defined as robots designed for a total manipulator mass, a maximum force, and/or a maximum speed exceeding any of the values for a Robot Class I.

Therefore, Robot Class I involves smaller, lighter robots more likely to work around humans, while Class II are larger, heavier robots. The standard allows Class I robots to do certain collaborative tasks without any safety features.

For Class II robots to be used in collaborative applications, one or more of the following safety-oriented technologies must be added, depending on the application:

- Speed and separation monitoring (SSM): Ensures a minimum distance between robot and human is maintained during operation; this can be accomplished by integrating a safety laser scanner into the application, which uses reflected laser beams to detect if a human or other object is present.

- Power and force limiting (PFL): Ensures that even if a robot and human come into contact, the human is unharmed.

- Hand-guided controls (HGC): Workers control the robot motion for a collaborative portion of the task, and the robot executes an automated task once the worker presses a hold-to-run button.

Both classes of robots will need certain common safety functionality, such as hardwired emergency stop (estop) buttons. The larger Class II robots will have a greater need for protected/restricted zone safety devices, which can include cage door interlock switches, light curtain sensors, safety laser scanners, and other forms of a presence-sensing device (PSD). These measures are imperative to detect workers in the protective/restricted zone of a robot.

Additionally, most robots include some option for a teach pendant, which is a type of human-machine interface (HMI) usually cable-connected in such a way as to allow the user to move about with it a bit.

Teaching pendant requirements for safe cobots

Robot teach pendants may have digital elements but also might need some specific hardwired devices, depending on the applications. Safety functions for these applications are required to be hardwired, as opposed to touchscreen controls. A key example of a hardwired function other than an e-stop is an enabling switch.

Figure 2: The IDEC HExB series of three-position enabling switches comply with IEC 60947-5-8, permitting robots to operate only when users are consciously holding the switch in a mid-position. Equipment will stop if the operator squeezes too hard or releases the switch. Source: IDEC

An enabling switch—sometimes colloquially known as a “dead man’s switch” or more formally as a three-position enabling (3PE) device—is a hardwired switch arranged on the teaching pendant where it is convenient for the user to grip it. When the operator desires the robot to run, they must positively hold the enable switch in a mid-position to enable hold-to-run control functionality.

Letting go of the enabling switch for any reason, or gripping the switch too tightly such as in a panic or electric shock situation, immediately stops robot operation. These switches are specified by IEC 60947-5-8 (Figure 2).

For Class II robots, it is mandatory for the teaching pendant to include a 3PE device due to the hazard involved if an operator is in proximity to the robot in manual mode. For Class I robots, a risk assessment must be performed to see if this is necessary.

For Class I robots, if sufficient risk reduction is achieved through a risk assessment, the use of 3PE switch is not required.

However, under the new standard for Class I robots, if a teach pendant is used to initiate motion for common manual tasks such as maintenance or troubleshooting, then integrating a 3PE switch is likely the best way to achieve compliance.

Or, if the robot is operated using HGC, then a 3PE switch may be a good option.

How interface designs can comply with the new standard

Robot OEMs typically create their own teach pendants, whether fully customized, or assembled from other commercial off-the-shelf (COTS) components, or a combination of the two. Smaller robots with fewer axes just need basic pendants, but larger and more capable robots often have pendants with touchscreen HMIs.

Moving forward, these OEMs may need to adapt their designs to include 3PE switches that comply with IEC 60947-5-8. This could involve costly revisions to custom hardware. However, there is another option on the market that can help OEMs deliver a complete and safe solution, while taking advantage of the latest COTS interface technology.

Modern consumer-grade tablets already offer the display size and computing power needed to provide a rich user interface and visualization experience for many types of automation. These could be useful for industrial applicaitons, but this is only possible if the tablet can be physically protected, supplied with power, connected to networking, and incorporate the necessary hardwired safety/control components.

Figure 3: The IDEC HT4P Safety Commander can be used by OEMs to incorporate digital HMI capabilities using tablets, while complying with ISO 10218 series standards for safety. Source: IDEC

A new mobile device holder is available to meet all these requirements (Figure 3). Key features include:

- Incorporates wired power and networking, a hardwired estop with LED indicator and retrofittable guard, and a hardwired 3PE switch

- Capability to integrate other hardwired devices such as a manual/automatic standard or keyed mode selector switch, start/restart switch/ reset switch, and/or a normal stop switch

- Adjustable grippers to hold tablets up to 33 cm (13 in.)

- Ability to lock the holder in vertical/portrait or horizontal/landscape orientation.

- Can be handheld by left- and right-handed users, with a hand or shoulder strap to minimize fatigue.

- Rated IP54, with a wide operating temperature range, and drop resistance tested to 1.2 m (3.9 ft.)

- Available cable lengths of 5 through 20 m (16.4 to 65.6 ft.), and a wall-mount bracket.

Using this mobile device holder for robotics applications, OEMs can quickly and economically develop and deploy teach pendants compliant with the ISO 10218 series standards while using inexpensive tablets to provide a comprehensive HMI.

Standards change to keep robots safe

Robot safety standards are changing and are expected to impact the rapidly growing market share of cobots. However, OEMs can approach this evolution as an opportunity to provide safer equipment, with greater features that differentiate their offerings.

Standards-compliant 3PE switches and mobile device holders are cost-effective COTS products that can add significant flexibility and capability to robot designs, while ensuring compliance with associated safety standards.

About the author

About the author

Luiz Shida is a marketing specialist at IDEC Corp. and responsible for safety product marketing. Since joining IDEC Japan headquarters more than seven years ago, he has become certified as a safety sub-assessor in Japan. Shida is also a specialist in safety products.

The post What evolving robot standards mean for implementations of cobots appeared first on The Robot Report.